Ensuring safety in workplaces, transportation, and the environment hinges on one simple tool—hazard stickers. They may look small, but their impact is a lot wider. Proper labeling can prevent accidents, save money, and keep you on the right side of the law. If you want to protect your team, community, and business, knowing everything about hazard stickers is the first step. This guide covers everything you need to know—types, regulations, design tips, and real-life examples. Let’s get started.

Understanding Hazard Stickers: What Are They and Why Are They Essential?

Workplace safety depends greatly on clear hazard communication. Hazard stickers are vital tools that warn workers about dangerous substances. These stickers help prevent accidents and keep your business compliant with OSHA and GHS standards. But managing Safety Data Sheets (SDS) and turning that info into correct hazard stickers can be tricky. Mistakes happen when you don’t have a system in place. That’s where SDS management solutions step in—they make the process easier, faster, and more accurate. This article shows how effective SDS management improves hazard sticker creation, saves time, and keeps your workplace safe.

Definition and Purpose of Hazard Stickers

Hazard stickers are bright, easy-to-read labels that mark dangerous materials or conditions. They act like warning flags—letting people know about risks before they get hurt. Whether it’s a spilled chemical or a broken machine, the hazard sticker’s role is to be alert. Think of them as safety signposts in a busy street—clear and noticeable.

1) The Role of Hazard Stickers in Safety Compliance

Safety rules require hazard stickers. They follow strict regulations from agencies like OSHA and GHS. These labels help workplaces stay compliant. For example, a manufacturing plant that labels chemicals correctly can prevent fires and injuries. Without proper labeling, companies risk fines or worse—serious accidents.

2) Benefits of Using Hazard Stickers

Hazard stickers do more than warn—they save lives. They:

- Make hazards clearly visible.

- Help prevent accidents and injuries.

- Make compliance simple, reducing legal risks.

- Support insurance claims after incidents.

In short, these stickers are small but powerful tools that protect everyone.

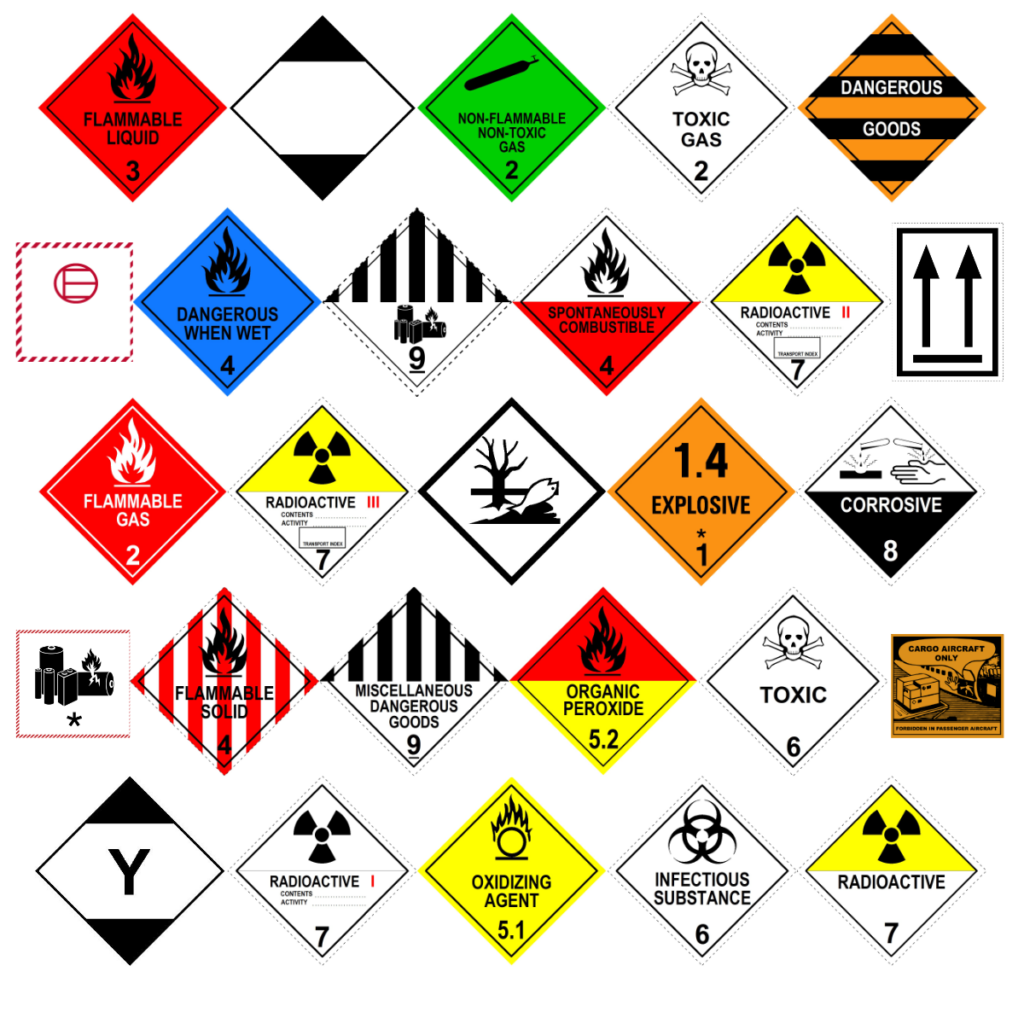

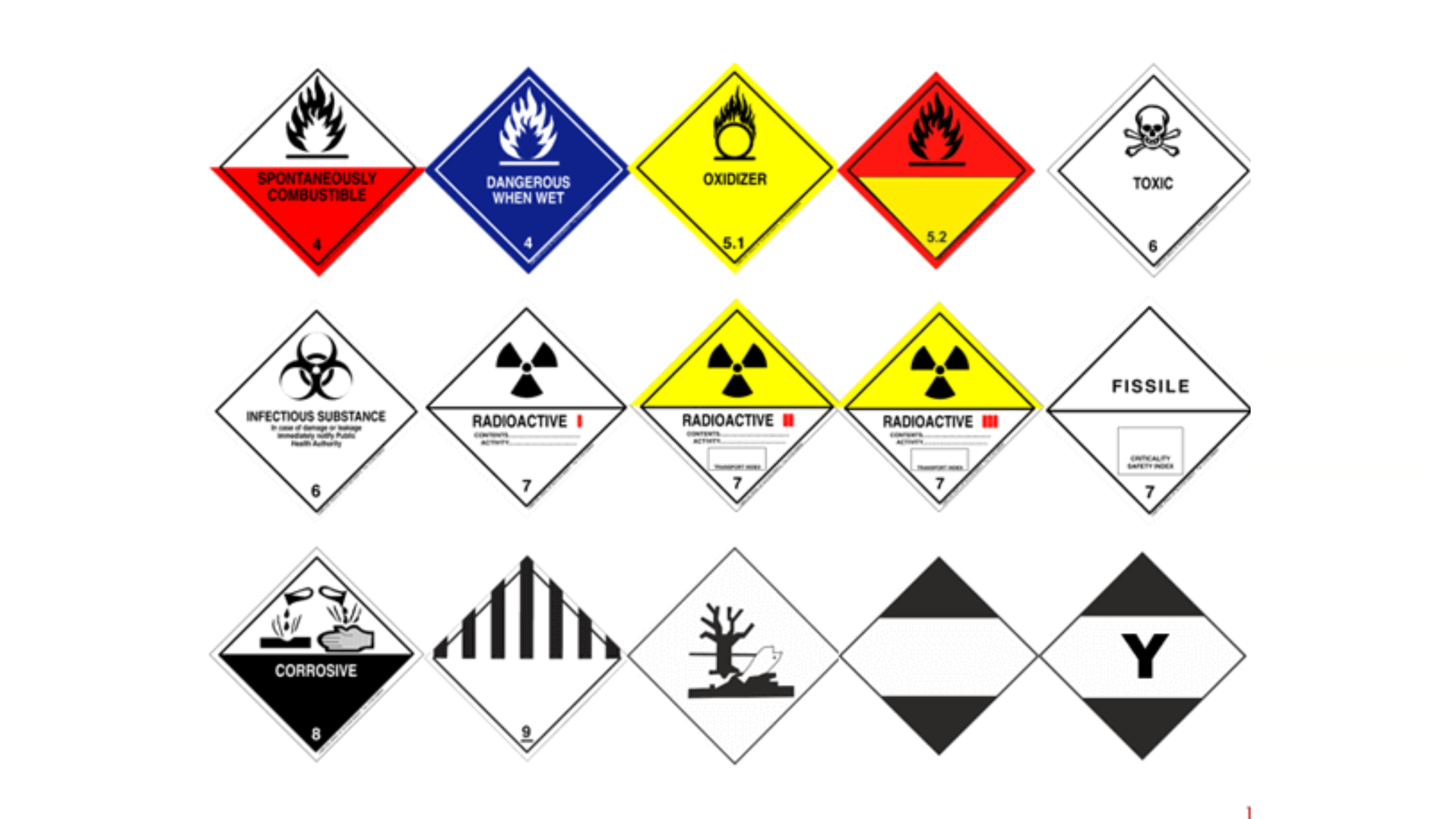

Types of Hazard Stickers: A Complete Overview

Different hazards need different labels. Knowing the types helps you choose the right stickers.

-

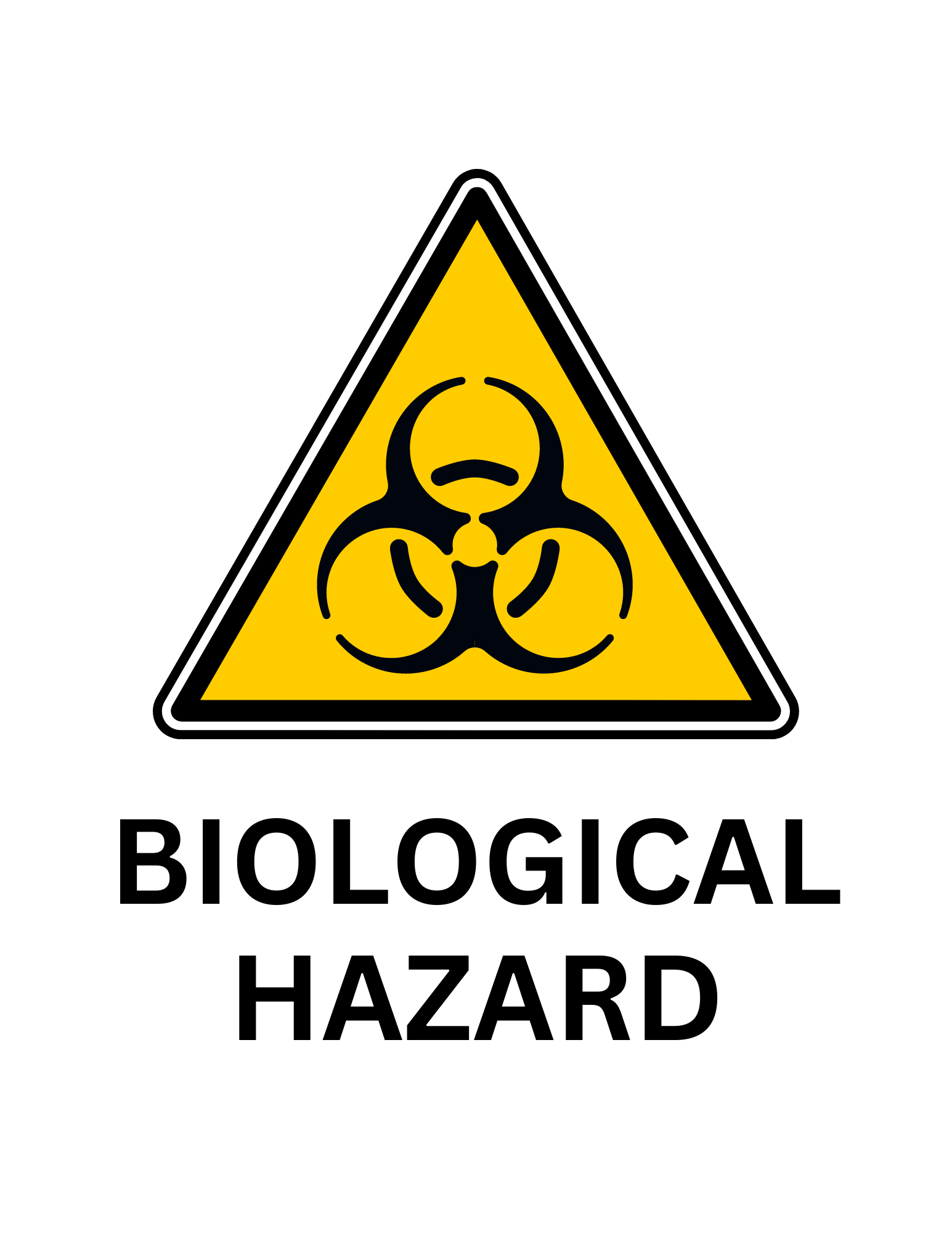

Biological Hazards Stickers

Biohazard stickers are used in healthcare, laboratories, or waste disposal. They mark infectious risks like bacteria or viruses. These stickers usually feature biohazard symbols in bright yellow or orange. They tell staff to handle such items with extra care.

-

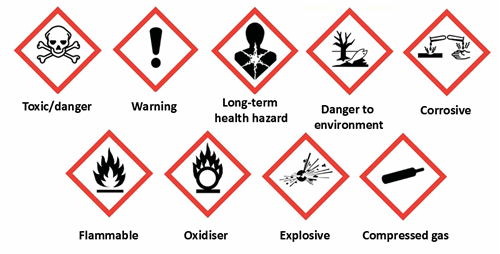

Chemical Hazard Stickers

Label chemicals that could burn, poison, or react dangerously. They include symbols for corrosive, flammable, toxic, or reactive chemicals. These use GHS pictograms—like the flame for flammable or the skull for toxic. Color codes help, with red indicating danger and yellow for caution.

-

Physical Hazards Stickers

A physical hazard sticker will show risks from machinery, electrical hazards, or falling objects. Common symbols include lightning bolts for electrical risks or falling debris icons. These labels keep workers alert about physical dangers in their environment.

-

Environmental Hazards Stickers

This hazard sticker indicates waste, emissions, or substances harmful to nature. They ensure compliance with laws like EPA rules. These stickers usually feature symbols for pollutants or spills, warning about environmental damage.

-

Specialized Hazard Stickers

Custom hazard stickers are designed for unique risks. For example, a chemical plant might label specific process hazards. Many include QR codes linking to detailed safety info or procedures, making them more informative.

Regulatory Standards and Compliance Guidelines

Following regulations isn’t just smart; it’s required. Here’s what you need to know.

-

OSHA and OSHA 1910 Regulations

OSHA demands proper hazard labeling in workplaces. OSHA 1910 standards spell out what labels should include. Deadlines for compliance have come and gone, but many companies still miss the mark. Failing to label hazards can lead to fines, shutdowns, or accidents.

-

Globally Harmonized System (GHS)

GHS is an international standard for classifying hazards and labeling. It aims to make labels understandable worldwide. GHS symbols are now common in most industries, making safety info clear across borders.

-

Additional Regulations and Industry Standards

✔️DOT (Department of Transportation): Labels for transporting dangerous goods.

✔️EPA: Rules for environmental hazard labels.

✔️Industry-specific rules: Healthcare uses biohazard symbols; chemical manufacturing follows strict GHS rules.

-

Consequences of Non-Compliance

Ignoring hazard labels can cost dearly. Companies face fines, legal trouble, or even shutdowns. Data shows non-compliant businesses are twice as likely to have accidents. Failing to label properly isn’t just risky—it’s costly.

Designing and Implementing Effective Hazard Stickers

How do you create hazard stickers that work? Follow these tips.

✅Key Elements of an Effective Hazard Sticker

- Clear symbols: Use universally recognized signs.

- Legible text: Big, simple font that’s easy to read.

- Color coding: Red for danger, yellow for caution, green for safety.

- Durable materials: Water-resistant, UV-proof stickers that last.

✅Best Practices for Placement and Visibility

Place stickers at eye level or near hazard sources. Avoid covering them with dirt or paint. Use reflective or glow-in-the-dark stickers in low-light areas for extra visibility.

✅Customization and Digital Labeling

Create custom stickers for hazards unique to your industry. QR codes can link workers to safety data sheets or procedures. It’s a smart way to add information without cluttering the label.

✅Maintenance and Inspection

Regularly check stickers. Replace faded or damaged labels immediately. Keep an electronic record of safety signs for audits and inspections.

Selecting the Right Hazard Stickers for Your Industry

Picking the right stickers depends on your work environment.

Factors to Consider

- Type of hazards present

- Indoor or outdoor settings

- Exposure to chemicals or weather

- Specific regulations you need to follow

Sources and Suppliers

Choose vendors known for quality. Look for stickers that meet OSHA, GHS, and industry standards. Test samples before buying large quantities.

Budgeting and Cost-Effectiveness

Compare prices carefully. Bulk ordering reduces costs. Custom stickers may seem pricey but pay off by reducing risk and liability.

Real-World Applications and Case Studies

Seeing hazard stickers in action can clarify their value.

-

Industrial Safety

Factories that label all chemicals and machinery see fewer accidents. Clear signage guides workers and prevents costly mistakes.

-

Transportation and Logistics

Shipping companies use hazard stickers to mark dangerous products. Proper labeling ensures safe transport and compliance with laws.

-

Healthcare and Laboratories

Biohazard stickers protect staff from infectious materials. Proper labeling saves lives and prevents contamination.

-

Environmental Protection

Waste disposal sites use hazard stickers to mark spill-prone areas. They alert workers quickly and help follow regulations.

Actionable Tips for Implementing Hazard Stickers Effectively

-

Conduct thorough hazard assessments.

-

Train employees about sticker meanings.

-

Check labels regularly—replace damaged ones.

-

Keep documentation for audits.

-

Choose high-quality, weather-resistant stickers.

The Role of SDS Management in Hazard Communication Compliance

-

The Importance of Accurate Hazard Information

OSHA and GHS require hazard labels to show accurate, clear info about chemical risks. Labels must include hazards, precautions, and first-aid info. If this info is wrong or outdated, workers may get injured or sick. OSHA can hit businesses with hefty fines, and safety accidents can cause long-term harm. So, maintaining precise data is critical to avoid these risks.

-

How SDS Management Ensures Regulatory Compliance

Your SDS updates should match what’s on hazard stickers. When a SDS is revised, the info on labels must also change. Failure to update labels can lead to compliance issues, fines, and safety violations. For example, a company didn’t update SDS info after a chemical change. That mistake led to fines and a chemical spill incident. Proper SDS management keeps everything synchronized, avoiding costly penalties.

-

Benefits of Automated SDS Management Systems

Using automated systems can increase compliance significantly. These tools can track SDS revisions and alert you when updates are needed. They help generate hazard stickers automatically, reducing manual work and errors. Statistics show that companies with automation report 30-50% fewer compliance violations. Faster updates mean your hazard stickers always match the latest SDS data, preventing safety mishaps.

Integrating SDS Management with Hazard Sticker Processes

-

Centralized SDS Database for Quick Access

Having one simple-to-access SDS database makes it easier to find the right data fast. Whether you’re creating a sticker or answering a safety question, quick access reduces mistakes. Instead of searching through paper files, a centralized system saves time and improves accuracy.

-

Streamlined Label Content Generation

With SDS data stored digitally, hazard stickers can fill in automatically. This eliminates manual entry errors and ensures consistency across all labels. Your team will produce clear, standard warnings every time. Consistent labels help workers understand hazards better and promote safer work habits.

-

Real-Time Updates and Version Control

Chemical info can change quickly. It’s key to update hazard stickers right when SDS revisions happen. Some incidents like spills or exposure happen because outdated labels misled workers. Using a system that controls versions and updates labels instantly can save lives and prevent accidents.

Practical Tips for Effective SDS Management and Hazard Sticker Application

-

Implementing a Robust SDS Tracking System

Choose software that fits your business size and needs. Look for features like automatic updates, cloud access, and easy search functions. Customizing your system can help you stay compliant and keep all SDS info organized.

-

Training Staff on Hazard Communication and SDS Handling

Make sure workers know how to find SDSs, understand hazard labels, and update stickers when necessary. Regular training keeps knowledge fresh and reduces the chance of errors.

-

Regular Audits and Quality Checks

Set a schedule to review hazard stickers and SDS data. Check for outdated info or incorrect labels. Regular inspections catch problems early and keep safety standards high.

-

Leveraging Technology for Automation and Error Reduction

Connect your SDS management with labeling software. Automated label creation and updates to cut down on manual mistakes. Technology makes compliance less burdensome and more reliable.

Conclusion

Managing SDS effectively is crucial for accurate hazard stickers and workplace safety. When your SDS info stays current and is integrated with your labeling process, you prevent mistakes and stay compliant. Automated systems make updates easier and faster, reducing risks and ensuring workers get clear warnings. Evaluating and improving your SDS management practices can strengthen safety in your workplace. Act today—review your SDS processes and harness technology to turn hazards into safety successes.

Leave A Comment