Introduction:

Effective hazard communication is the foundation of workplace safety. OSHA Standard 1910.145 establishes the critical requirements for designing, applying, and maintaining warning signs and tags that protect workers from occupational hazards. By standardizing how hazards are communicated across industries, this regulation ensures that employees can quickly recognize dangers and respond appropriately, potentially preventing serious injuries or fatalities.

Understanding the Purpose and Scope of OSHA 1910.145

OSHA 1910.145 specifies comprehensive requirements for accident prevention signs and tags intended to indicate and define specific hazards that could cause accidental injury to workers or members of the public or result in property damage. The standard applies to nearly all workplaces across general industry but does not apply to signage designed for public streets, highways, or railroads, nor to plant bulletin boards or safety posters used primarily for employee education.

The fundamental objective of 1910.145 is to create uniformity in hazard communication. Just as traffic signs maintain consistent design and meaning across different geographic locations, workplace safety signs must maintain uniform design and appearance so that workers, regardless of industry or location, instantly understand what hazard they are encountering.

Classification of Signs and Tags

OSHA 1910.145 establishes distinct categories of safety signs and tags, each serving a specific purpose and following defined design requirements.

-

Danger Signs: Immediate Hazard Warnings

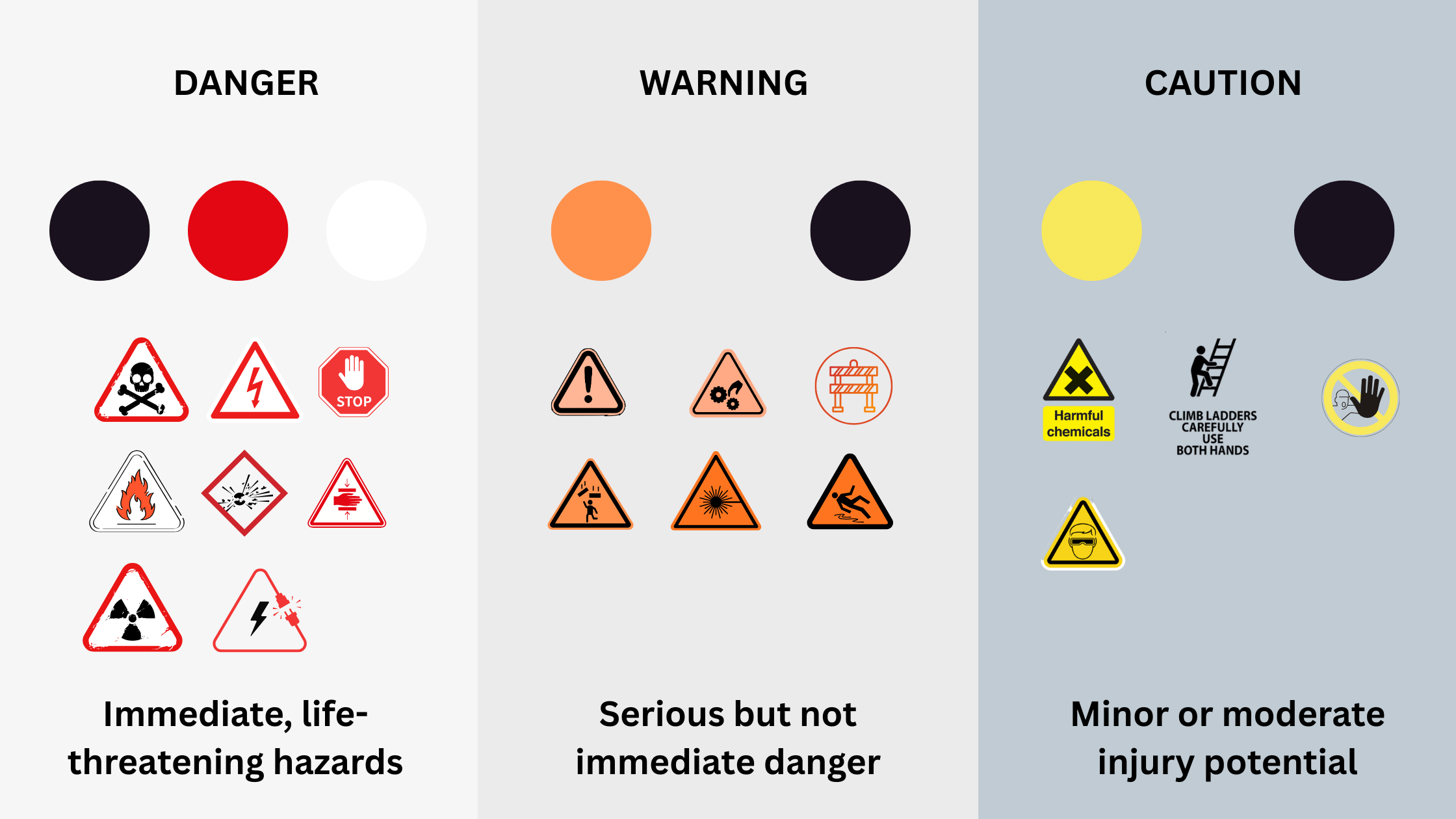

Danger signs communicate the most serious level of workplace hazard. These signs indicate an immediate threat that presents a risk of death or serious injury to employees. All employees must be instructed that danger signs signal immediate danger requiring special precautions.

Danger signs are designed with a distinctive three-color scheme consisting of red, black, and white, with opaque glossy finishes to ensure visibility and professional appearance. The traditional format features a red panel in the upper section containing the word “DANGER,” positioned above a white panel that provides additional hazard information. This two-panel format creates a visual hierarchy that workers instinctively associate with life-threatening hazards.

-

Caution Signs: Potential Hazard Warnings

Caution signs warn employees about potential hazards or unsafe practices that could result in minor or moderate injury if not avoided. These signs use a yellow background with black lettering and a black panel to ensure high visibility and contrast that draws worker attention while distinguishing them from danger signs.

Caution signs serve a crucial role in preventing common workplace injuries. The yellow color standard follows ANSI specifications for opaque glossy finishes, ensuring consistency and reliability in recognition across different lighting conditions.

-

Safety Instruction Signs: Guidance and Information

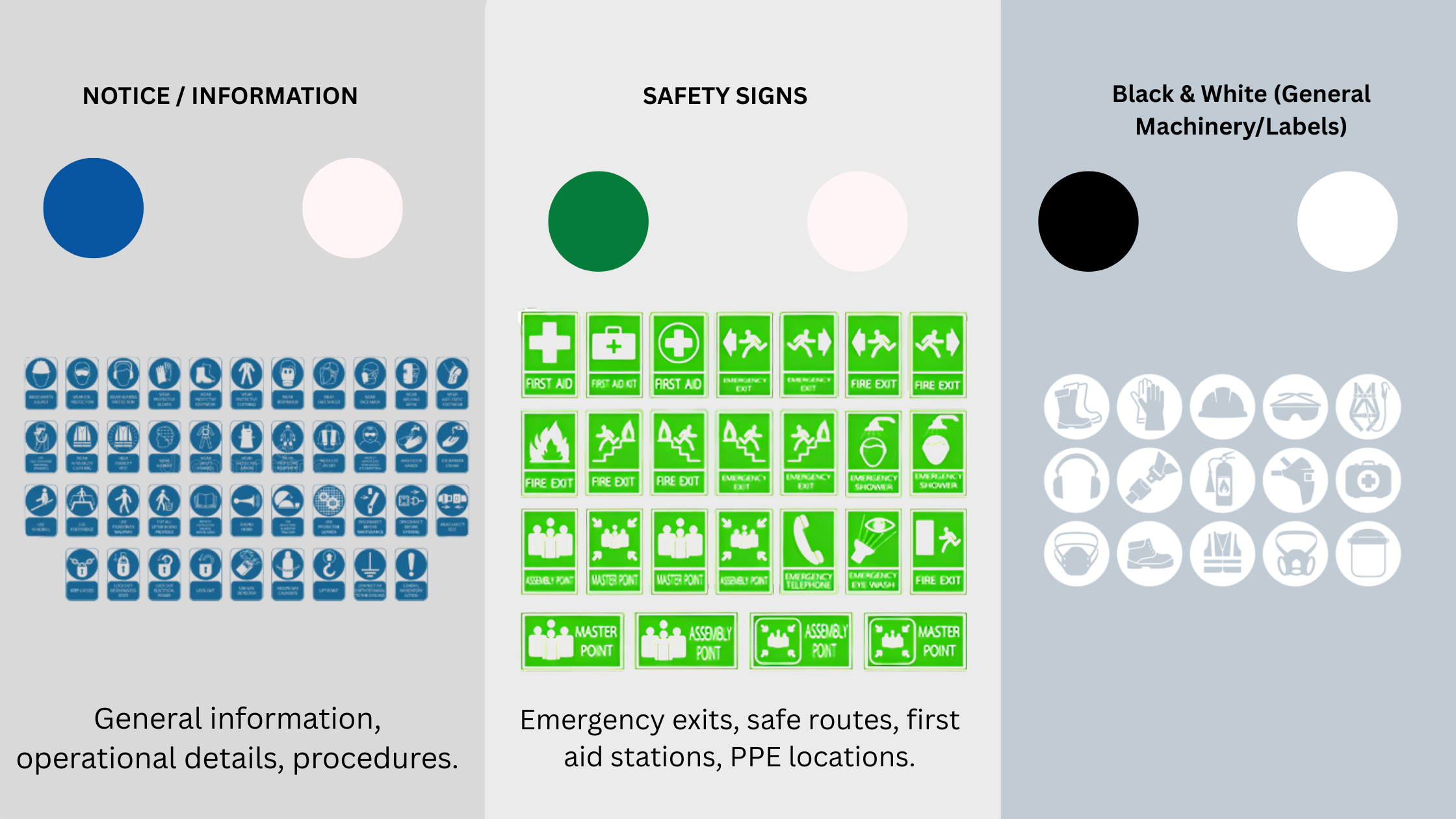

Safety instruction signs provide general instructions, suggestions, and guidance related to safety measures. These signs establish a white background with a green panel and white lettering, with any text on the white background displayed in black.

Safety instruction signs are commonly associated with emergency facilities and safe practices. They are frequently displayed on eyewash stations, safety shower locations, emergency exits, first aid stations, and areas designated for personal protective equipment use.

-

Warning Tags: Intermediate Hazard Communication

Warning tags represent a hazard level between caution and danger, addressing medium-severity hazards that could cause serious injury. OSHA recommends using an orange or predominantly orange color with contrasting lettering for these tags. While not mandatory for signs, this color scheme is strongly recommended to meet regulatory requirements and industry best practices.

-

Accident Prevention Tags: Temporary Hazard Communication

Accident prevention tags serve a fundamentally different purpose than permanent safety signs. Tags are temporary devices designed to prevent accidental injury or illness when hazardous conditions are unexpected, out of the ordinary, or not readily apparent. Tags are particularly valuable during temporary work situations, equipment maintenance, or when permanent signage cannot be quickly installed.

Tags need not be used where signs, barricades, or other positive means of protection are already in place. Once the identified hazard is eliminated or the hazardous operation is completed, tags must be removed.

Design Specifications for Signs and Tags

-

Structural and Safety Requirements

OSHA requires that all signs and tags meet specific physical design criteria to prevent additional hazards during installation and use. All signs must feature rounded or blunt corners to eliminate sharp edges, burrs, splinters, or other sharp projections that could injure workers or damage protective equipment. The fastening devices, such as bolts, must be positioned so they do not create additional hazards.

These seemingly minor design requirements reflect OSHA’s comprehensive approach to safety—preventing signs and tags themselves from becoming workplace hazards.

-

Color Specifications and Standards

The OSHA 1910.145 standard incorporates the American National Standard Z53.1-1967 for precise color specifications, ensuring consistency across manufacturers and industries. Colors must be opaque glossy samples to provide adequate visibility, contrast, and professional appearance under typical workplace lighting conditions.

-

Wording Requirements

Sign and tag wording must be easily read, concise, and readily understood by all employees who may be exposed to the identified hazard. Effective safety signage incorporates several key principles:

Wording should be easily read and legible from the required viewing distance. Signs must contain sufficient information to be easily and quickly understood without requiring detailed explanation from supervisors. Messages should make positive, rather than negative, suggestions about safety measures. All wording must be accurate in fact and reflect genuine workplace hazards.

Tag Classification and Requirements

-

Danger Tags

Danger tags are reserved exclusively for major hazard situations where an immediate hazard presents a threat of death or serious injury. They must never be used for minor hazards, as overuse diminishes their warning impact.

-

Caution Tags

Caution tags address minor hazard situations involving non-immediate or potential hazards presenting a lesser threat of employee injury. These tags communicate warnings about unsafe practices or temporarily hazardous conditions that do not rise to the level of immediate danger.

-

Biological Hazard Tags

Biological hazard tags identify the actual or potential presence of hazardous biological agents in equipment, containers, rooms, materials, or experimental animals containing viable infectious agents presenting a risk of death, injury, or illness. OSHA recommends using fluorescent orange or orange-red coloring with contrasting lettering for these tags.

-

General Tag Criteria and Standards

All required tags must meet comprehensive criteria outlined in 1910.145(f)(4), including:

- Signal words: Tags must clearly display either “Danger,” “Caution,” “Warning,” or “Biological Hazard” as the signal word.

- Readability distance: The signal word must be readable from a minimum distance of five feet, or greater distance as warranted by the specific hazard. This ensures workers can recognize the warning before entering a hazardous area.

- Major message: Tags must include a specific message indicating the hazardous condition or instruction to be communicated. This message may be presented using pictographs, written text, or both.

- Understandability: Both the signal word and major message must be understandable to all employees who may be exposed to the identified hazard.

- Attachment security: Tags must be affixed as close as safely possible to their respective hazards using positive attachment means such as string, wire, or adhesive that prevents loss or unintentional removal.

Employee Training and Hazard Communication

Critical Training Requirements

OSHA requires that all employees receive comprehensive training on the meaning of various tags and signs used throughout the workplace and the special precautions necessary for each hazard level. This training requirement reflects the reality that warning signs and tags are only effective when employees understand their meaning and implications.

Creating Hazard Communication Programs

Successful hazard communication programs integrate warning signs and tags into broader occupational health and safety initiatives. Organizations should:

- Conduct thorough workplace hazard assessments to identify all potential dangers requiring signage or tags.

- Develop visual communication plans that specify which signs are needed at specific locations.

- Ensure consistency between signs, tags, and other safety communication methods used throughout the facility.

- Establish regular maintenance schedules to keep all signs and tags visible, legible, and in good condition.

Maintenance and Compliance Considerations

-

Sign and Tag Maintenance

Active safety signs require ongoing maintenance to remain effective. Any sign that is vandalized, becomes rusted, is fading, or is coming off the affixed location must be immediately replaced. Signs that are no longer relevant to workplace hazards must be promptly covered or removed.

Regular facility inspections should include verification that all required signs remain visible, legible, and properly affixed. Damaged or deteriorated signage can inadvertently communicate that hazard communication is not a priority, potentially undermining the entire safety culture.

-

Compliance Assessment

All new signs and replacements of old signs must comply with OSHA 1910.145 specifications. Organizations can verify compliance by:

Confirming that all danger signs follow the red-black-white color scheme with appropriate text. Verifying that caution signs use yellow and black colors with correct design. Ensuring all tags meet the appropriate signal word, readable distance, and attachment requirements. Confirming that employee training records document that workers understand the meaning of all signs and tags used in their work areas.

Non-compliance with 1910.145 is consistently among the top OSHA violations cited across industries, contributing to thousands of workplace accidents annually. Studies indicate that well-placed, properly designed safety signs can reduce workplace accidents by up to 80 percent when integrated into comprehensive occupational health and safety programs.

Practical Implementation for Different Workplace Settings

-

Manufacturing Environments

Manufacturing facilities typically require extensive signage due to machinery hazards. Danger signs should clearly mark areas with moving parts, pinch points, and electrical hazards. Machine guards require warning signs indicating potential cutting, crushing, or electrocution hazards. Maintenance areas require tags clearly marking equipment undergoing lockout/tagout procedures.

-

Chemical Storage and Handling Areas

Chemical facilities must use comprehensive hazard communication, combining OSHA 1910.145 signs and tags with Safety Data Sheet (SDS) information and GHS-compliant labeling. Danger signs mark areas with chemically reactive or toxic substances, while caution signs warn about fire hazards, skin irritants, or respiratory sensitizers. Biological hazard signs must mark areas containing viable infectious agents.

-

Construction and Temporary Hazard Areas

Construction sites extensively use accident prevention tags for temporary hazards, equipment under maintenance, or unauthorized areas. These tags provide critical warnings during temporary work phases before permanent safeguards can be installed.

Conclusion

OSHA 1910.145 establishes the comprehensive regulatory framework ensuring that workplace warning signs and tags effectively communicate hazards, protect workers, and prevent occupational injuries and illnesses. By understanding the distinct purposes of danger, caution, and safety instruction signs—and properly implementing accident prevention tags—organizations create visual communication systems that enhance workplace awareness and demonstrate commitment to employee safety.

Success in 1910.145 compliance requires integrating sign and tag requirements into broader hazard communication and occupational health and safety programs. Organizations that invest in proper design, regular maintenance, and comprehensive employee training transform safety signage from mere regulatory compliance into a proactive defense against workplace hazards.

Leave A Comment