Colors serve a purpose far beyond aesthetics. They can instantly communicate critical information, especially in situations where every second counts. Probably for this reason, the Occupational Safety and Health Administration (OSHA) emphasizes the use of standardized color codes in the workplace—to ensure that important safety information is communicated clearly and immediately. It helps employees quickly identify hazards and take necessary safety measures.

Safety at the workplace is not just about rules and training—it’s also about making information easy to understand quickly. One simple and effective way to do this is through color coding. These color codes act as visual signals, guiding people on what to do and what to avoid.

Each color carries a specific meaning—but how many color codes are there, and what do they actually signify? This blog answers those questions and helps you and your organization create a safer workplace by using OSHA-recommended color codes effectively

Color Coding: In Brief

Color coding means using certain colors to share safety messages quickly. For example, red usually means “stop” or “danger,” and green means “safe” or “go.”

In a workplace, these colors help show where safety equipment is, which areas are dangerous, or which paths are safe to walk on. This helps everyone—whether they are new or experienced—understand safety warnings without reading long instructions.

Why is Color Coding Important?

Color coding is important for several reasons:

✅Quick Recognition

When there’s an emergency, every moment is crucial. Color-coded signs and labels help workers spot danger or safety equipment right away. Such codes reduce the need to read long instructions. For example, a red sign immediately tells someone there’s a risk or fire hazard nearby. This quick recognition can save lives.

✅Universal Understanding

People from different backgrounds may speak different languages. But colors are understood by almost everyone. Generally, a yellow sign, for example, means “be careful,”. The meaning is easy to understand for everyone, regardless of their language or where they come from. This makes the workplace safer for everyone, especially in teams with diverse workers.

✅Improved Compliance

OSHA and other safety organizations require certain color codes to be followed. If a company uses these codes correctly, it shows that they are meeting safety standards. This helps them avoid legal issues or fines during inspections.

✅Reduces Chances of Accidents

Clear, color-coded signs help warn workers before they step into a dangerous area or come into contact with harmful materials. This lowers the risk of injury. For example, a bright orange or yellow sign can signal a physical danger. When accidents are prevented, work runs more smoothly, and equipment stays safe from damage.

OSHA-Recommended Color Coding and their Meanings

Source Link: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.145AppA

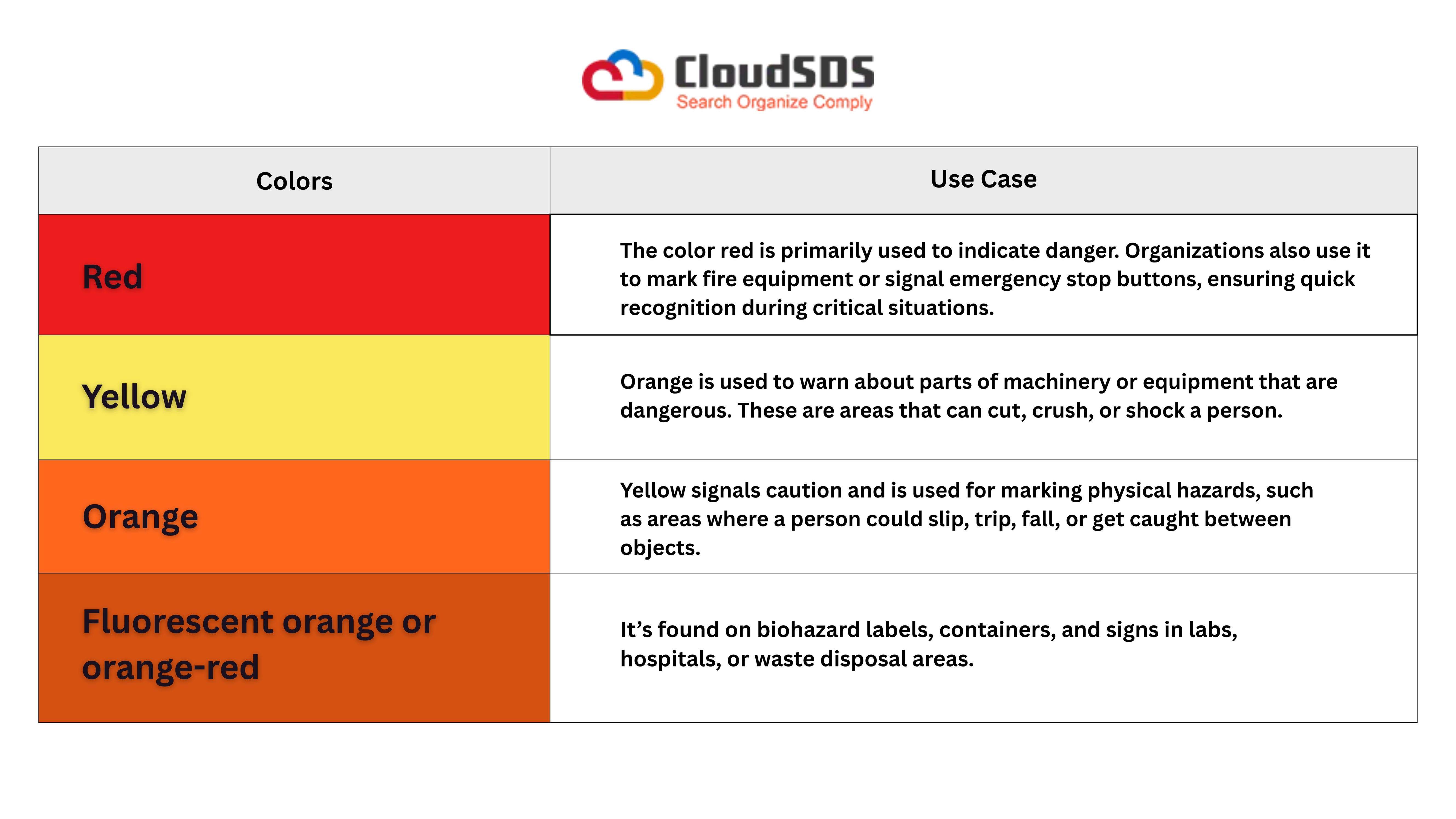

OSHA, in alignment with ANSI (American National Standards Institute) standards, has outlined color codes that should be used in various workplace settings:

1) Red:

Source link: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.144

The color red is primarily used to indicate danger. Organizations also use it to mark fire equipment or signal emergency stop buttons, ensuring quick recognition during critical situations.

Where It’s Used:

- Fire Protection Equipment:

Fire extinguishers, fire alarm boxes, and other firefighting tools are identified with red so they can be located quickly during emergencies.

- Flammable Liquids:

Safety cans or containers holding flammable liquids with a flash point at or below 80°F must be painted red.

- Danger Signs:

Any signs or labels that warn of immediate danger (such as “DANGER – HIGH VOLTAGE”) must be red to grab attention instantly.

- Emergency Stop Devices:

Red is the required color for emergency stop bars, stop buttons, or switches on hazardous machinery. These are vital in immediately halting equipment during emergencies.

Why it Matters:

- Instant Recognition of Danger:

Red is universally understood to signal danger or stop, allowing workers to react quickly in hazardous situations.

- Fire Safety Readiness:

Clear red markings help workers find fire extinguishers and alarms faster—especially in high-stress situations.

2) Orange

Orange is used to warn about parts of machinery or equipment that are dangerous. These are areas that can cut, crush, or shock a person.

Where It’s Used:

- Machine Guarding Areas: Orange can be painted or labeled on machines where dangerous moving parts are located. For example, cutting blades, gears, or rotating shafts that pose a risk when exposed.

- Electrical Panels and Equipment: Used on panels or switchgear that may carry live electricity, orange markings help alert workers to the risk of electric shock and remind them to proceed with caution.

Why It Matters:

- Prevents Life-Threatening Injuries: By clearly marking areas where machinery can cut, crush, or electrocute, it reduces the chances of accidental contact with hazardous equipment.

- Supports Safe Maintenance Practices: Technicians and engineers rely on these visual cues during repair work to know which parts of the equipment must be handled with extra caution.

3) Yellow

Yellow signals caution and is used for marking physical hazards, such as areas where a person could slip, trip, fall, or get caught between objects.

Where It’s Used:

- Floor Markings: Yellow lines or tape are placed on floors to guide foot traffic and separate walkways from equipment zones. This helps keep employees safely away from moving machinery or forklifts.

- Moving Equipment Zones: It is used around areas where machinery moves or where workers may come into contact with moving parts, like conveyor belts.

Why It Matters:

- Prevents Accidents: By catching the eye and signaling “be careful,” yellow markings and signs help employees slow down and pay attention in areas where accidents are more likely to happen.

- Encourages Safe Movement: When workers know where to walk, where not to stand, and what to avoid, it reduces the likelihood of injuries related to tripping, slipping, or collisions.

4) Fluorescent Orange/Orange-Red

This bright shade warns of biological risks, such as exposure to infectious materials or biohazard waste.

Where It’s Used:

It’s found on biohazard labels, containers, and signs in labs, hospitals, or waste disposal areas.

Why It Matters:

It helps prevent exposure to dangerous pathogens and ensures workers handle these materials with extreme care.

How Can Companies Follow or Utilize these Color Codes?

To use OSHA’s color coding effectively, companies can follow these simple steps:

-

Audit Your Workplace

Look around and check where color coding is needed. You need to start the audit specifically near machines, storage areas, emergency exits, or hazardous zones.

-

Label and Mark Clearly

Once you know where to use color codes, apply them using materials that are easy to see.

- Use high-visibility paint, colored floor tape, or clear signs.

- Avoid faded or confusing colors.

-

Train Your Employees

Teach workers what each color means and why it matters. Use posters and quick reference charts to help your employees know what each color means and what actions they should take when they see them.

-

Review Regularly

Inspect color-coded areas to make sure markings are still visible and relevant. In case required, repaint or replace signs and tapes if they are faded or worn out.

-

Use Digital Tools

Modern safety software can make it easier to manage color coding. Some tools offer digital mapping, labeling templates, and checklists to help track safety zones. These systems also help with planning and ensure your facility stays in line with OSHA rules.

Conclusion:

Color coding might look simple, but it plays a big role in keeping workplaces safe. OSHA’s color guidelines help workers quickly spot dangers, avoid accidents, and act fast during emergencies. When companies use these colors the right way—and do it consistently—they create a safer space for everyone. No matter your industry, following OSHA’s color coding system is an easy, effective way to improve safety and stay compliant.

Leave A Comment