The safe transportation and handling of hazardous materials (HAZMAT) relies on a globally recognized system of signs, labels, and placards designed to communicate risks swiftly and effectively. This guide examines the nine classes of HAZMAT materials, the structural components of warning signs, regulatory frameworks governing their use, and best practices for ensuring visibility and compliance. By integrating U.S. Department of Transportation (DOT) standards with international systems like the Globally Harmonized System (GHS), this report provides a detailed analysis of how HAZMAT signage mitigates risks in industrial, commercial, and emergency contexts. Key findings include the critical role of color-coding in hazard identification, the legal obligations of carriers under 49 CFR §172.500, and advancements in sign placement strategies to optimize emergency response outcomes.

A Brief Overview on HAZMAT

Hazardous materials, or HAZMAT, pose significant risks to people who may be exposed to them, whether they are occupants of a building where the materials are stored, people in nearby structures, or first responders arriving on the scene of an incident. The wide variety of hazardous materials that exist come in many different chemical compositions and physical states, each presenting their own unique dangers. To assess the potential hazards of a particular material, it’s critical to consider the specific state and way it will be stored or handled. This diversity of materials and associated risks means there is also great variation in the construction requirements, fire protection systems, handling procedures, and emergency response tactics needed to mitigate the dangers. A standardized system of markings and labeling is essential for quickly conveying the general hazards of a material.

The Nine Hazard Classes

HAZMAT materials are categorized into nine classes based on their physical and chemical properties, as defined by the DOT and international transportation regulations. These classifications ensure uniformity in risk communication across logistics networks.

Class 1: Explosives

Explosives are subdivided into six divisions based on their detonation risk. Division 1.1 includes substances with mass explosion potential, such as dynamite, while Division 1.6 covers extremely insensitive materials like certain blasting agents. Placards for explosives feature an orange background with a black explosion symbol, alerting responders to potential blast or projectile hazards.

Class 2: Gases

This class encompasses flammable gases (e.g., propane), non-flammable gases (e.g., nitrogen), and toxic gases (e.g., chlorine). Flammable gases use red placards, non-flammable gases employ green, and toxic gases are marked with white placards bearing a skull-and-crossbones symbol.

Class 3: Flammable Liquids

Gasoline, acetone, and ethanol fall under this category, identified by red placards with a flame symbol. Combustible liquids with flashpoints above 60.5°C (e.g., diesel) require distinct labeling to differentiate them from more volatile substances.

Class 4: Flammable Solids

Subdivided into flammable solids (4.1), spontaneously combustible materials (4.2), and dangerous substances when wet (4.3), this class uses red-and-white striped placards for wet hazards and blue for self-reactive compounds.

Class 5: Oxidizers and Organic Peroxides

Oxidizers like hydrogen peroxide accelerate combustion, marked by yellow placards. Organic peroxides, which pose both fire and health risks, require specialized handling instructions alongside their labels.

Class 6: Toxic and Infectious Substances

Toxic materials (6.1), such as pesticides, use white placards with a skull symbol. Infectious substances (6.2), including medical waste, are labeled with biohazard symbols on white backgrounds.

Class 7: Radioactive Materials

Yellow placards with a trefoil symbol denote radioactive cargo. The inclusion of activity levels (e.g., “Radioactive III”) helps responders assess contamination risks.

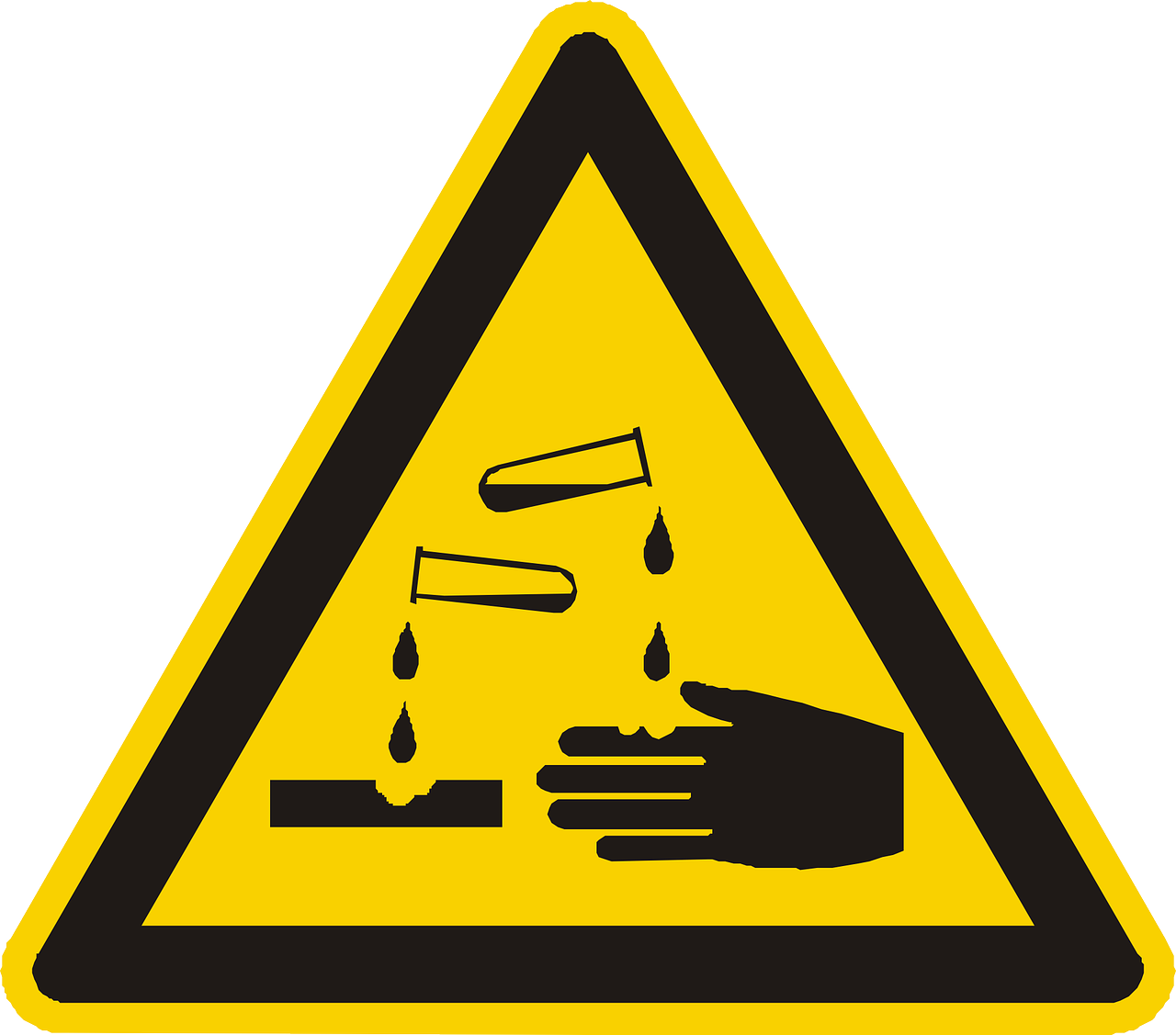

Class 8: Corrosives

Acids and alkalis, such as sulfuric acid, are identified by black-and-white placards featuring a test tube dripping liquid onto a hand and surface.

Class 9: Miscellaneous Hazards

This catch-all category includes environmentally hazardous substances and elevated-temperature materials, marked with white placards bearing black vertical stripes.

Components of HAZMAT Signs

Structural Anatomy

HAZMAT placards incorporate six elements to convey critical information:

- Hazard Class Number: Positioned at the bottom, the number (1–9) corresponds to the material’s primary risk category.

- UN/NA Identifier: A four-digit code (e.g., UN1203 for gasoline) links the material to standardized handling protocols.

- Compatibility Letters: Used in some contexts to indicate chemical groups that can be safely transported together.

- Color Coding: Red signifies flammability, yellow oxidation, and white toxicity, creating instant visual recognition.

- Text Descriptors: Phrases like “Inhalation Hazard” or “Marine Pollutant” provide supplementary warnings.

- Graphics: Symbols like flames, skulls, or radiation trefoils enhance comprehension across language barriers.

Regulatory Exceptions

Small quantities of hazardous materials, such as limited-quantity consumer goods, may be exempt from full placarding requirements under 49 CFR §172.500. However, carriers must still mark packages with proper labels and shipping papers.

Regulatory Frameworks and Compliance

DOT and PHMSA Standards

The Pipeline and Hazardous Materials Safety Administration (PHMSA) mandates that placards meet size (250 mm x 250 mm) and durability standards to remain legible during transportation. Materials not properly labeled risk penalties under the Hazardous Materials Regulations (HMR).

Placarding Thresholds

Placards are required when transporting:

- Over 1,000 kg of a single hazardous material.

- Any quantity of high-risk substances (e.g., explosives, toxic gases).

- Bulk packaging (e.g., tankers) containing Class 3, 6, or 8 materials.

ANSI Z535 and Sign Design

The ANSI Z535.4 standard governs safety sign formatting, requiring:

- Signal Words: “Danger,” “Warning,” or “Caution” in bold, uppercase letters.

- Pictograms: Symbols occupying at least 15% of the sign’s area.

- Text Contrast: A luminance contrast ratio of at least 5:1 between text and background.

Visibility and Placement Strategies

i) Optimal Mounting Practices

Research indicates that placards mounted 45–66 inches above ground align with drivers’ sightlines, while emergency signage placed at 78 inches improves visibility for first responders.

ii) Color and Contrast Considerations

Fluorescent materials like orange red (for explosives) and green (for non-flammable gases) enhance detection in low-light conditions. Retroreflective coatings ensure legibility under headlights or flashlights.

iii) Case Study: NFPA 704 Diamond

While not a transportation placard, the NFPA 704 diamond used in fixed facilities illustrates advanced hazard communication. Its four quadrants rate health (blue), flammability (red), instability (yellow), and special hazards (white), using a 0–4 severity scale.

International Harmonization: GHS and HAZMAT

1. GHS Pictograms

The Globally Harmonized System (GHS) supplements DOT labels with nine pictograms, including:

- Flame Over Circle: Oxidizers (GHS03).

- Skull and Crossbones: Acute toxicity (GHS06).

- Environment: Aquatic toxicity (GHS09).

2. Integration Challenges

While GHS labels dominate safety data sheets (SDS), transportation placards prioritize DOT classifications. Multimodal shipments often require dual labeling, increasing compliance complexity.

Applications in Transportation and Emergency Response

1. Carrier Responsibilities

Drivers must verify placard integrity before departure, replacing damaged signs per 49 CFR §172.519. In accidents, first responders use placards to:

- Identify leaked substances using ERG (Emergency Response Guidebook) codes.

- Establish evacuation zones based on toxicity or flammability of radio.

- Select appropriate personal protective equipment (PPE).

2. Training and Certification

The DOT requires HAZMAT employees to complete recurrent training on:

- Placard selection and placement.

- Compatibility of loading rules.

- Emergency shutdown procedures for compromised cargo.

Conclusion

HAZMAT signs form an indispensable layer of defense against chemical, radiological, and biological risks in supply chains. By adhering to DOT specifications, leveraging color psychology, and adopting emerging technologies like retroreflective inks, stakeholders can reduce incident severity and regulatory non-compliance. Future advancements may include digital placards with RFID tracking, yet the foundational principles of clarity and universality will remain paramount. Organizations are advised to conduct annual audits of their labeling systems and invest in workforce training to align with evolving PHMSA and ANSI guidelines.

Leave A Comment